We use cookies to make your experience better. Read more

TPU filament

As low as €16.99

inc. VAT

Regular Price €19.99inc. VAT

In stock

Only %1 left

SKU

000028517015

Why choose 3DTrcek TPU 90A filament?

⭐Elastic filament: Resistant to impact, deformation, and wear

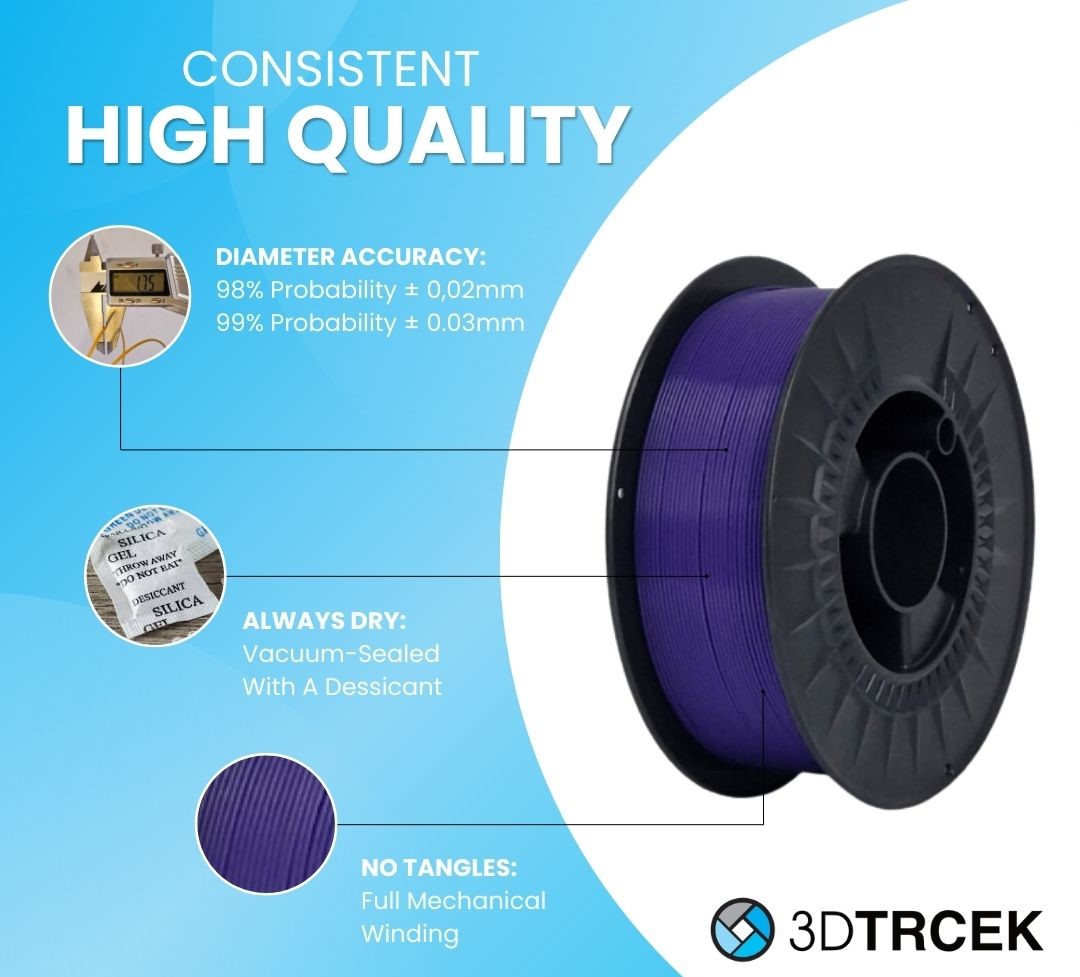

✨High precision: Constant diameter 1.75mm +/- 0.03mm

⚡Adaptable flexibility: Dependent on infill density

❤️Structural resistance: UV rays and many chemical solutions

- Compatible with most common 3D printers

- Precise winding, no jamming while printing

- Made in Slovenia

3DTrcek TPU 90A Filament

Popular among thousands of creators for its reliable quality. Made in Slovenia, with over 10 years of experience in 3D filament manufacturing and 45 years in plastic processing. TPU filament offers flexibility, durability, and resistance to wear to your prints.

Exceptional Flexibility:

3DTrcek TPU filament with a hardness of 90 Shore A, offers excellent elastic properties and is easier to print than softer TPU filaments. Despite its hardness, it still provides good surface adhesion, making it suitable for various applications, from toys and cosplay props to hinges, seals, anti-slip bases, and even prosthetics.

Printing:

Using a printer with a direct drive extruder is recommended when printing TPU filaments as they tend to bend inside a Bowden tube. This reduces the deformation of the filament before the melting zone in the print head, allowing for more consistent extrusion. Due to its excellent bed adhesion and minimal shrinkage, there is no risk of the model warping and detaching during printing. As TPU filament easily absorbs water it's recommended to dry it before use to achieve satisfactory results.

Quality Guarantee:

Precise mechanical winding and thorough inspection ensure that the filaments do not tangle. Each spool is vacuum-packed with a desiccant within 5 minutes of production, ensuring long-lasting quality. The filament contains no recycled material, ensuring a stable diameter of 1.75mm +/- 0.03 mm and minimal ovality.

Compatibility:

Due to the bending of the filament in the PTFE tube, it is recommended to use a printer with a direct extruder for the best results. Additionally, TPU filaments are NOT compatible with multi-material systems. With over 10 years of experience in developing 3D filaments, 3DTrcek produces only the best TPU filaments, ensuring exceptional results on all popular FDM printers, such as Bambu Lab, Creality, Prusa, Anycubic, Elegoo, etc.

Chemical, Mechanical, and Thermal Properties:

TPU offers good resistance to water, oils, and greases. Coupled with UV resistance, it is suitable for industrial use and outdoor installations. TPU boasts exceptional toughness and wear resistance as well as temperature resistance up to 95℃.

Download 3DTrcek TPU Technical Data Sheet

Post-processing:

Due to its good interlayer adhesion and wear resistance, TPU is challenging for post-processing.

Storage:

Store 3DTrcek TPU filament in a dry, dark place in an airtight bag with desiccant at temperatures between 0 ℃ and 40 ℃. TPU quickly absorbs moisture, so we recommend drying it in a filament dryer or oven at 50°C for 6-12 hours before use.

Packaging:

Available in 50g, 250g and 700g spools. Contact us at [email protected] for orders of the larger spools in specific colors.

Spool Dimensions:

Net Weight (kg) | 0,25 | 0,7 |

Spool Width (mm) | 44 | 68 |

Outer Diameter (mm) | 160 | 200 |

Inner Diameter (mm) | 52 | 52 |

Spool Weight (g) | 130 | 220 |

Printing Recommendations:

For printing TPU filament, it is recommended to use a printer with a direct extruder to prevent filament bending in the Bowden tubes. When printing TPU with overhanging geometry, it is good practice to reduce the minimum print speed.

Printing temperature | 230℃- 250℃ (240℃) |

Speed | 10 - 50 mm/s> ( 45 mm/s) |

Volumetric flow | 4 mm³/s |

Flow ratio | 1,08 @45mm/s, |

Bed Temperature | 30 ℃- 50 ℃ (35℃) |

Retraction | 0,4 mm @ 30 mm/s |

Drying | 50 ℃ / 6h |

*Settings for Bambulab P1S equipped with a 0.4mm nozzle and textured PEI base plate.

** Recommended settings serve as a starting point for optimal print configuration. Although they usually work for most printers, we recommend experimenting outside these parameters based on the specific properties of your printer.

If you have any questions or need technical assistance, contact us at [email protected] or by phone: +386 (0)1 242 83 60.

Download 3DTrcek TPU Bambu Lab profiles

FAQ:

Is TPU compatible with the Bambu Lab AMS system?

No, TPU isn’t compatible with AMS system as it gets stuck in the feeding tube and can not retract back onto the spool. But you can still print it on Bambu Lab printers, just place the filament on the back spool holder.

Do you take back failed prints and recycle them?

We currently do not have the technology for recycling, but we are working to make this possible in the near future.

TPU filament

Please complete your information below to login.

Sign In

Create New Account